Boosting productivity: the best Kanban tools for project managers

Unlock your team's potential with Kanban tools! Streamline workflow, combat multitasking, and boost productivity with our top picks. #ProjectManagement #KanbanTools

Master Kanban for optimal project management! Unlock productivity, streamline workflows, and boost outcomes with our step-by-step guide and free PowerPoint template. Dive in now! #ProjectManagement #Kanban

In the dynamic environment of project management, where adaptability and efficiency are a necessity, Kanban methodology has stood the test of time and continues to revolutionize successful project execution.

As a project manager, you’re no stranger to the constant demands of your role — managing teams, timelines, and deliverables with precision. So, whether you’re new to Kanban or looking to deepen your understanding, this comprehensive guide will equip you with the knowledge and tools needed to streamline workflows, boost productivity, and enhance project outcomes.

From explaining the core principles of Kanban to providing practical examples and a free downloadable PowerPoint template, this blog post will transform your project management approach and help you harness the incredible potential of Kanban tools.

So, let’s dive in and discover how Kanban can reshape your project management landscape.

The Kanban board is a popular workflow visualization strategy that aims to maximize efficiency and avoid overcapacity using cards, columns and swimlanes. Its origins can be traced back to the “two-bin system” used by Spitfire production facilities in the UK during WW2.

During the late 40s and early 50s, Taiichi Ohno, who was working as an industrial engineer for Toyota, developed and perfected a similar system which became known as “Kanban” (カンバン in Japanese), which means “signboard”.

The name “Kanban” originates from the cards used on a board to track inventory and production within the factories in order to limit excess buildup of parts or concurrent tasks.

Toyota also drew inspiration from the way supermarkets work. In short, customers come in, pick only the items they need from the shelves and leave; afterwards, the supermarket replenishes only the items that have been purchased, therefore limiting the buildup of excess inventory.

Taiichi Ohno, whom some regard as the father of the system, maintained that any successful application of the Kanban strategy requires following strict and clearly defined rules.

For instance, Toyota lives by these six principles:

The application of the Kanban principles in the knowledge sector (IT, software development, etc.) came much later, in 2004. Pioneers like David Anderson, Peter Drucker, Darren Davis, Corey Ladas, Rick Garber and numerous others proponents of Agile saw the potential of this approach.

They joined efforts and, after years of testing and tweaking, the system we now know as “Kanban boards” was born. David Anderson’s first work on the matter, “Kanban: Successfully Evolutionary Change for your Technology Business”, is still one of the most comprehensive guides available today.

Let’s discover why Kanban became such an important visualization tool in recent years.

In a nutshell, Kanban helps teams reduce costs and increase efficiency by visualizing and limiting work in progress (or “WIP”) inventory, thus improving the workflow. You might be saying to yourself: “that sounds abstract and vague”, but we’ll get into more details in a minute. Also, when you think about it, many other project management strategies promise more or less the same thing, right?

Well, the effectiveness of any PM tool, be it timelines and Gantt charts, Gap Analysis, Critical Path, etc., depends on how you use it. The Kanban board’s unique visualization style and limits set on the WIP encourage you to examine your company’s process cycles and identify exactly where problems are causing any blockages. Faults like bottlenecks, delayed work or too much WIP will immediately become apparent on a Kanban board.

Similarly, using the Kanban limits on the work in progress, together with a “pull” system (which means that a team only takes on a task if there is the capacity for it) prevents work overload and promotes a fair distribution of responsibilities.

Collaboration and communication are further strengthened by sharing your Kanban boards, as multiple departments can see the tasks and their current place in the cycle. Teams that are dispersed geographically and normally collaborate in a shared virtual space probably benefit the most from the Kanban methodology. The tasks on the boards ensure that everyone can work independently without overlapping efforts.

Now, let’s find out why so many project managers rely on using Kanban boards regularly for a healthy workflow.

Among other things, PMs are directly responsible for creating realistic schedules for projects, allocating tasks, tracking progress, and ensuring deliverables are provided on time. These are all aspects the Kanban methodology excels at.

Here are a few ways in which this type of boards greatly simplifies the lives of project managers everywhere:

Two KPIs are generally considered the king and queen of the Kanban world: cycle time and throughput. The first one, cycle time, refers to the duration required for a task to navigate your process or, to put it another way, how long a task takes from start to finish. The second one, throughput, counts the number of tasks that are completed within a predefined timeframe. Measuring these variables can offer important insight into productivity fluctuations over time.

Like timelines, one of the greatest assets Kanban brings aboard is its highly visual and intuitive nature. Seeing the path of tasks traveling along the workflow makes it easy to spot bottlenecks and problematic practices that are holding back your teams. And, with shared boards, everyone can pitch in and come up with creative solutions to optimize the flow.

Many companies, particularly in the early stages, opt for an Agile style of management to gain the flexibility required in our ever-changing business landscape. This is why Kanban-style roadmaps are an increasingly popular alternative to the rigid, fixed deadlines found in Waterfall project plans: the freedom to reassess priorities according to your current circumstances.

“But won’t this level of flexibility lead to completely chaotic delivery times?”, you may ask. Quite the opposite, as long as we stick with Little’s Law, which states that, ideally, the entry and departure rate of tasks on the board should remain roughly the same value. In Kanban, this is achieved through limits set on the WIP.

Kanban is the epitome of the Lean management style, which comes as no surprise considering its origins that we discussed earlier. In knowledge work, time is perhaps the most valuable commodity and Kanban boards are known to drastically reduce waiting times, thanks to their flexible nature. In turn, this also means increased focus on completing tasks and, again due to the limits on WIP, less time wasted on alternating between tasks.

The people best equipped to help optimize your company’s processes are those who are using them every single day. As a project manager, you will benefit immensely from leveraging the expertise of your teams and encouraging them to speak out whenever possible. Furthermore, Kanban boards allow you to delegate more tasks without fear of missing critical updates on the project.

At its core, Kanban is an Agile method of project management (although it can be used with other PM strategies) that relies on a visual approach to showcase the progress of a project. Using even the simplest version of a Kanban board – a three-column To Do / Doing / Done model – anyone can see:

Each task starts out in the “To do” column farthest to the left and is gradually pulled by team members or project manager into the “Doing” column when the actual work starts, then into the “Done” column to the right when the task is completed. Here’s a visual illustration:

The innovation brought by Kanban boards is represented by the limit placed on the “Doing” or “WIP” column. Tasks cannot and should not be moved there unless there is capacity for the work. This is decided by the teams executing the task. In Lean methodologies, this is referred to as a “pull system”. To best understand it, think of your average vending machine: products are only restocked once they have run out.

Next, let’s discover the principles behind Kanban.

Let’s assume that you’ve been going to the gym for a while, hoping to build some muscle mass. Unfortunately, the process is slow and your motivation is fading, so you’re weighing the obvious options: giving up, changing your routine or taking steroids.

Fortunately, after talking to your gym buddies, they suggest a fourth option: every workout, you increase the duration of exercises that are targeting the muscle groups you want to bulk up by 30 second increments. It works! You end up gaining mass and, because the increase is gradual, you barely feel the difference.

Kanban’s philosophy is to first assume that you have an intangible foundation, in the form of your existing processes, hierarchical structures, policies, etc. Rather than tearing everything down and starting from scratch, which would be terribly disruptive, Kanban seamlessly integrates into your company’s existing modus operandi.

Adopting Kanban allows you to examine how your workflow can be streamlined by way of small, gradual and incremental changes.

Let’s discover the 4 major principles governing this model:

Implementing Kanban is first and foremost about recognizing and understanding the value of your current processes, roles, responsibilities, communication venues and general workflow. This is perhaps the greatest strength of the methodology: making a business case for a strategy that requires absolutely negligible disruptions, improves efficiency and saves resources.

While it’s not as time-based as the Agile or Scrum frameworks that operate with sprints, Kanban still reclaims helpful concepts such as continuous development through small, compounding changes. Large-scale changes are often very difficult to implement and will certainly be met with resistance from various sources, due to various concerns.

For instance, the major stakeholders might be nervous regarding the costs of implementation, while lower-level positions could worry about not having a place in the hierarchy or completely changing their work routines. Kanban nips those anxieties in the bud.

This is another principle aimed at easing fears about the potential disruption caused by implementing a new PM model. Think of Kanban as a software update: it’s gently and gradually changing legacy features of the product without impacting major functionalities. The challenge comes from gaining people’s interest and support in work environments where change is slow, like a large organization.

Shared Kanban boards that everyone can access promote cooperation but also encourage everyone to take ownership and address the issues they discover. Of course, it’s also up to the management to create an environment where team members feel safe to speak out, take risks and develop their skillset.

Agile and Scrum have sprints and iterations, Waterfall works with linear sequential phases, while Kanban is pretty much all about states or statuses, represented visually as columns. All these PM methodologies tend to break down the workload into manageable tasks, but the lifecycle of the tasks is what sets them apart.

In Kanban, a project manager’s main concern is to always have a limited number of items in every column, particularly in the “Work-in-Progress” or “Doing” column. Tasks always move rightwards on the board.

Over the last 20 years, numerous industry players have embraced the Kanban methodology and successfully implemented it in their day-to-day processes.

Let’s look at some examples.

Not so long ago, Nike received some backlash from the public on the subject of substandard working conditions. To address it, leadership visited the production facilities and interviewed workers to discover what the most problematic issues were and how to address them.

The survey revealed that the main culprits were fluctuations in the order size and time, as well as late notice updates to the materials, so they decided to go for a more standardized demand and decline any post-deadline requests. Bonus points to them for introducing Nike Grind, a waste-reduction system that transforms old products into athlete training surfaces.

Jaguar is one of the many automotive manufacturers that took a page from Toyota’s playbook when they had to cut down the time-to-market for newer models (basically how long it takes for a new car to be designed, manufactured and shipped to the dealership). Implementing Kanban revealed long waiting time on design and concept feedback to be one of the major bottlenecks.

Their solution implied switching to a minimum viable concept strategy. That is, communicating only the necessary information for decision-making purposes to stakeholders. It worked brilliantly and Jaguar, following an extensive implementation of Kanban, is now one of the top lean manufacturing automakers.

The company struggled with finding the time to complete its planned projects. The solution turned out to be switching to a Kanban-style of PM and breaking down larger projects into manageable tasks that could be completed within short intervals.

They originally used a classical version of the board with the To do/Doing/Done columns and categorized tasks based on duration (short – 1 day, medium – 2 to 4 days, long – 1 week). Kanban helped Spotify minimize lead times and increase productivity without major changes in the employees’ daily routine. There are dozens and dozens of other examples from various industries of successful Kanban integrations, like Pixar, Zara, NextPhase or even the Seattle Children’s Hospital that you can find online.

So far, we’ve discussed the history, benefits and principles behind the Kanban board. It’s now time to learn what it takes to set one up and how you can tailor it to suit the needs of your enterprise.

Here’s how to get started in four simple steps:

Note: We consider that the assignee of a card is optional because Kanban is often used in conjunction with a pull system where teams and employees pick the cards on the board rather than having them assigned by another party.

In the Kanban framework, items that fall under the leftmost column of the board – usually the “To Do” column – are known as the “backlog”. They are essentially tasks that must be completed, but they have not yet been assigned to a team and they are not currently being worked on. Having a sound method of cataloguing, organizing and prioritizing the tasks in the backlog is crucial.

Because Kanban is pretty flexible and doesn’t impose deadlines, you need to make sure that people are first pulling the highest priority tasks from the “To Do” column into “Doing”. With virtual Kanban boards, you can add category labels to cards, like “Bug”, “Request”, “Urgent”, “Critical”, etc. and use the automatic sorting feature to always keep priority tasks at the top of the “To Do” pile. This approach also implies less backlog maintenance, as you won’t need to manually reorder them.

Visualization is, above all, about leveraging the human ability to process visual cues so much faster than any other channel of communication. It’s pretty much the reason why the popularity of project charts and graphics like timelines, Gantt charts, and Kanban boards has skyrocketed over the last years: visuals are able to convey complex information in an intuitive manner that our brain decodes instantly. When done correctly, of course.

Let’s find out how to create the best visualization for your workflow in Kanban:

Note: Keep in mind that introducing the Kanban board organization system is aimed at improving productivity, not adding another meaningless to-do for the sake of the leadership. That is why you should make sure the board always reflects reality accurately. Also, keep a close eye on scope creep.

WIP limits are almost synonymous with this methodology, as a 2022 report from State of Kanban shows, or it is at the very least the most popular practice among users.

This begs the question: how do you decide the WIP limits? While there isn’t any foolproof scientific formula you can apply to determine the optimal cap, here are couple of tips to help you get started.

When you’ve just begun implementing Kanban, the initial WIP limits might not accurately reflect the full capacity of your team. And that’s okay. Stick with the chosen values for 2-4 weeks; you will start to get an understanding of where you are currently and how you can finetune the limits.

If your WIP limit is too high, your team will likely revert to the old way of doing things, i.e., multitasking and context switching, just to meet the deadline. On the other hand, setting the bar too low translates into downtime, particularly when the team must wait for a third party to sign off on the work.

To find the sweet spot, you’ll need to keep monitoring productivity KPIs whenever you make changes to the WIP limit and determine if it’s had a positive or negative impact.

We mentioned a bit earlier there isn’t any hard and fast rule to determine how many items can exist in the WIP column concurrently. There are simply too many work environment variables to account for. However, a good place to start could be to set a WIP item limit equal to the number of team members plus one.

In other words, if you have 4 people on your team, your initial WIP threshold can be 5. From there, you can adjust it as required.

OK, but how do you use Kanban to improve processes in your day-to-day activity? Here are a few things to keep in mind when implementing Kanban across your business.

How do we define bottlenecks? Simply put, a bottleneck is a stage in the workflow where congestion causes delays or halts production downstream. They’re also known as the project manager’s worst nightmare, especially right before deadlines. Symptoms of bottlenecks may include:

There are two main types of bottlenecks to be mindful of:

The best way to uncover the bottlenecks and their origin is to perform a thorough analysis of your workflow. Here’s how you can get started:

When you are mapping a process, you are essentially trying to figure out:

Armed with this information, you can proceed to the next stage.

In addition to Kanban boards, timelines and Gantt charts can be very useful in this analysis, because they help you determine where the unaddressed work requests tend to cumulate. Involving the team members in this process can reveal valuable input and show the real underlying issues that lead to the bottleneck.

Your team is also a valuable asset when it comes to figuring out the optimal way to deal with the bottlenecks in a manner that won’t break the workflow. Nonetheless, don’t stop once a solution has been identified and approved for implementation. It’s always a good idea to conduct follow-up project evaluations and ensure its effect is positive.

Metrics are incredibly useful for figuring out how well your team is performing and where there is opportunity for growth. However, we need to make a distinction between useful and hindering metrics. We also need to employ each of them for the correct purpose.

For example, you could take the following criteria into account:

In the Kanban world, the most frequently employed metrics are Cycle time, Lead Time, Throughput, Team Performance and WIP, and these can be explored in different ways. Let’s first define them, for a better understanding.

To analyze these metrics and their impact on your project’s efficiency, there are a number of charts and diagrams that you can employ. Some of the most popular ones consist of:

The Lead / Cycle Time chart is utilized in measuring how long cycles take on average. More specifically, it takes a task with predefined parameters and helps determine the amount of time required to traverse all the columns on your Kanban board.

The CFD evaluates project health, the flow throughout various phases of the project, determines if there are any hurdles and tracks overall progress. Color coding the numbers of work items within each column makes it easier to see any blockers.

The Burndown chart is useful in visualizing the number of tasks planned versus the number of tasks completed. Assuming the teams maintain a relatively similar pace, it can help predict when a project will be completed and future performance.

Creating a Gantt chart or timeline in addition to your Kanban board is another method of crosschecking your metrics and better estimating your project’s completion date.

Feedback loops are another concept that Kanban borrowed from the Agile philosophy. Their role is to determine opportunities for growth and improvement, and then transform this potential into actionable items. Once the changes are implemented, we can then track the effects and begin addressing any challenges that arise.

Loops tend to have three main stages:

Feedback loops are being run continuously. Nurturing this process allows PMs to finetune virtually every problematic or potentially problematic aspect of the workflow. Naturally, all changes bring about both positive and negative aspects, so you’re looking at permanent ongoing work here.

The principles behind Lean philosophy also come from the original creator of the Kanban board, Taiichi Ohno. Therefore, it should come as no surprise that they work so well in conjunction with the Kanban framework. Let’s quickly explore what they are and how we can integrate them.

Value, in the Kanban context, comprises of every part of the work done that directly benefits the customer. Creating value, therefore, means trimming out the workflow parts that are unnecessary to the end result.

By analyzing your workflow through Kanban lenses – that is, breaking down the work into manageable chunks – you can begin to pick out what’s essential and what’s not. Value is not always direct, such as a feature that your customer requested; it can be indirect, in the form of a QA team finding bugs in the code that could have a negative effect on your sales.

Here we’re referring mainly to visualizing the workflow through the use of Kanban boards and/or other means, like timelines, Gantt charts or roadmaps. There isn’t much to be said about the classic version of the Kanban (To do/Doing/Done), but things get increasingly complex in certain specific context, like software or product development.

A smooth workflow, one without extensive idle times or bottlenecks is the key to any successful Lean project management implementation. The go-to strategy for this purpose is setting and adjusting WIP limits for maximum efficiency.

We’ve already discussed the pull system earlier, as a means for teams to self-govern the existing workload according to their capacity. It’s necessary to stress that the flexibility of the pull system should be balanced by the correct prioritization of the items in the backlog.

Both Kanban and Lean project management rely heavily on feedback and constant adjustments to the workflow. This, however, is only possible if all team members are given agency and encouraged to take ownership.

Selecting the right Kanban tool is a pivotal decision for project managers embracing this Agile methodology. The market offers a variety of options, each with its unique features and functionalities.

To make an informed choice, start by evaluating your specific project management needs. Consider the size of your team, the complexity of your projects, and the level of customization required. Look for a tool that aligns seamlessly with your project’s requirements.

Moreover, integrating your chosen Kanban tool with your existing project management system is crucial for ensuring a smooth transition. It’s essential that the tool complements your current workflow rather than disrupts it.

Assess the compatibility of the Kanban tool with your current software stack. Ensure that it allows for easy data sharing and updates between systems, reducing the need for manual data entry and the risk of information silos by easily sharing your board with stakeholders.

A well-integrated tool will streamline your processes, enhance communication, and provide a holistic view of your project’s progress, making it an invaluable asset for efficient project management. Remember, the right Kanban tool should not only suit your immediate needs but also accommodate your project’s growth and evolution over time.

For more details, check out our article that reviews the best software tools for Kanban boards on the market at the moment.

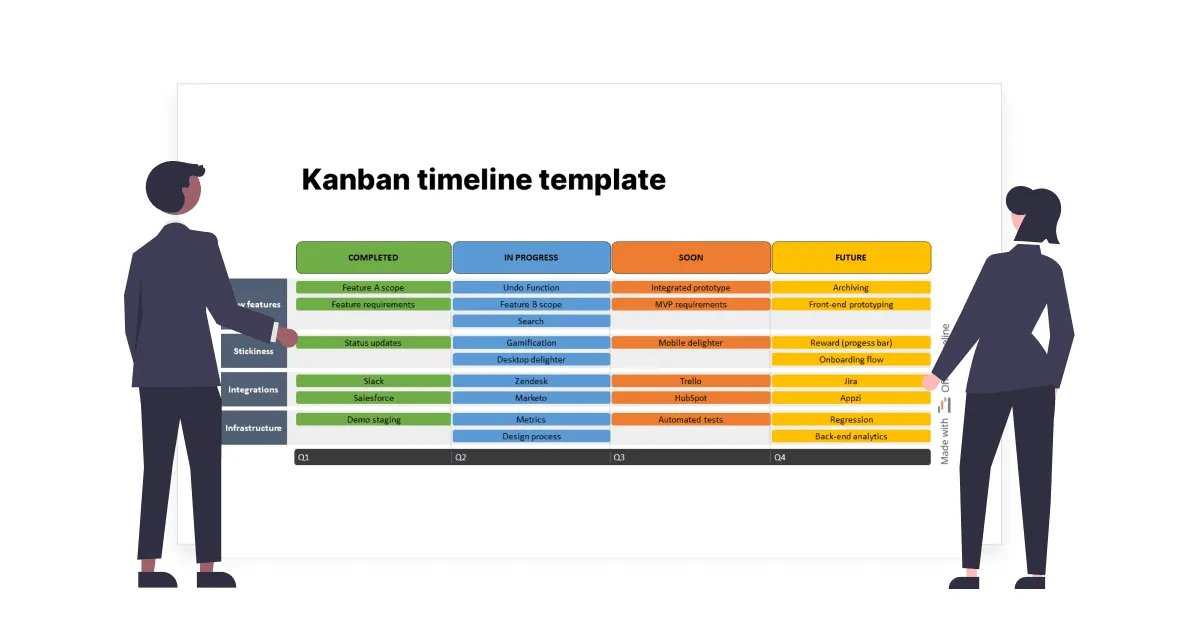

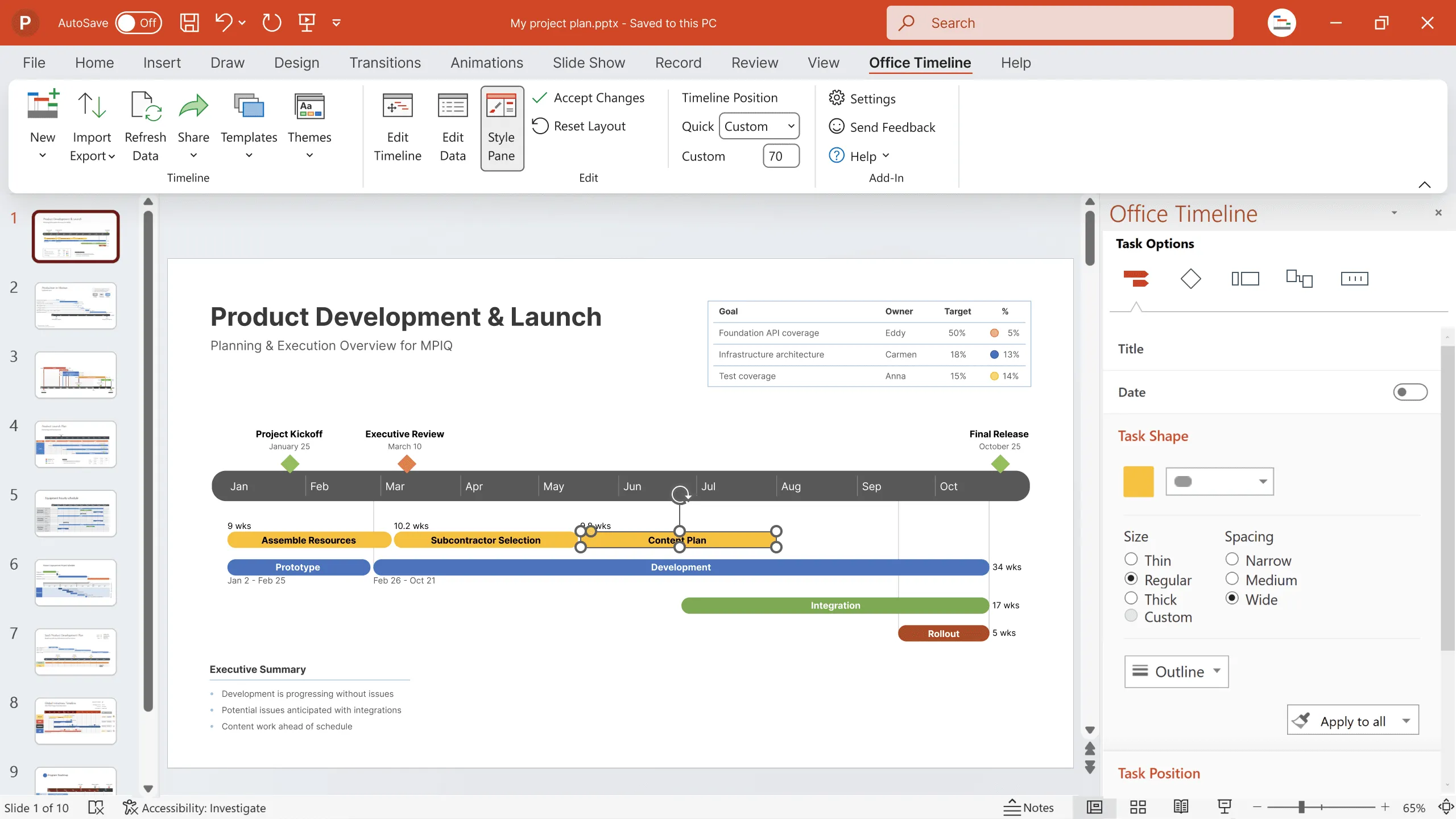

To help you manage your Kanban board seamlessly and present it with ease in your next project review meeting, you can try your hand with this free downloadable PowerPoint template, made with Office Timeline.

This template makes it easy for you to customize fields and colors to align with your organization’s workflow, directly within PowerPoint. However, for a more efficient and streamlined experience, we recommend using the Office Timeline add-in and its smart automation features.

For a first-hand look at Office Timeline's capabilities to create visually stunning Kanban boards, timelines, Gantt charts, roadmaps, or swimlane diagrams, you can explore our free 14-day trial. It also provides access to more advanced features like sub-swimlanes, dependencies, and multiple timescales, all these included in the tool's premium edition - a comprehensive solution worth considering.

As the business landscape changes continuously, enterprises have to adapt in order to remain afloat. Agile and Lean frameworks are all about reacting to new circumstances and updating their processes on the go, based on feedback. This is where the Kanban board comes in.

A flexible tool that leverages metrics to help create an optimal flow, promotes transparency and encourages collaboration, Kanban can be considered a nearly perfect instrument for planning and organizing work.

It leverages Lean and Agile principles to create PM strategies that limit wasted efforts and idle time, as well as promote team-wide accountability and initiative.

Remember that adopting Kanban is a simple and straightforward process that won’t require you to give up any of your existing systems: you can build the board on top of them. With minimal disruption and amazing results, it’s easily one of the best ways to increase productivity and efficiency.

And it only gets better from here! The advent of hybrid PM, AI-sourced analytics, virtual teams and an increasing interest in freelance work make Kanban an excellent solution for the foreseeable future.

Let’s have a look at the most frequently asked questions about Kanban in project management.

Kanban is a visual project management strategy that breaks down the workload into manageable tasks and sets WIP limits to minimize the number of items being addressed simultaneously. Priorities are set on each task, ensuring that urgent and/or critical issues are addressed first.

The philosophy behind Kanban is designed to minimize effort, decrease redundancy and avoid context switching. It’s principles are:

1. Start with what you do now;

2. Agree to pursue incremental, evolutionary change;

3. Respect the current process, roles, responsibilities, titles;

4. Encourage acts of leadership at all levels in your organization.

What separates Kanban from other workflow management strategies is the focus on states and visualizing tasks. A project manager using Kanban is more interested in reducing the number of WIP items. Conversely, a Scrum master will try to follow a set of principles and tested practices to structure and manage the workload.

Adopting Kanban on top of your usual project management framework will enhance productivity, offer better visibility and transparency, increase flexibility, improve focus and limit multitasking, and promote a collaborative work environment.

Setting up a Kanban board is extremely easy. You can use a physical whiteboard with 3 columns (To do/Doing/Done) and sticky notes, which will represent your work items. Select a process that you wish to improve, break it down into manageable tasks, write each task on a sticky note and place it in the correct column. When work begins on a task or when it is completed, move it into the correct column. Using a virtual board grants you access to many other life-quality improvements.

Mapping the processes that you are interested in and breaking them down into tasks will show you where the bottlenecks are hiding: in the parts where unaddressed work requests are piling up.

Kanban relies on Lead Time, Cycle Time, Throughput and WIP to evaluate the performance of a team on a given process.

There are many Kanban tools available, like Smartsheet, Monday.com, Jira, Asana, Kanbanize, Trello, etc. Be sure to review your current PM systems and check whether the Kanban board of your choice integrates with them.

Tim is Co-Founder & CEO of Office Timeline, a Seattle-based start-up that aims to rid the world of boring, uninspiring meetings.

Tagged With:

KanbanGet the advanced features of Office Timeline free for 14 days.

Unlock your team's potential with Kanban tools! Streamline workflow, combat multitasking, and boost productivity with our top picks. #ProjectManagement #KanbanTools